- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- News

- Answers

- Contact

- About

News

- 1

- 1

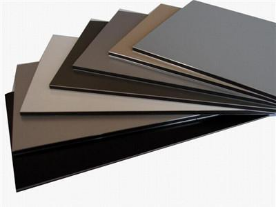

Aluminum steel clad plates: new materials lead innovation in the construction industry

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

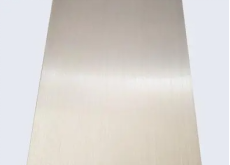

Aluminium clad steel sheet (referred to as "steel-aluminum alloy") are based on ordinary low-carbon steel panels. The manufacturing process is relatively intricate and needs multiple procedures. First, the aluminum and steel plates need to be surface treated to make the surface smooth and clean, coated with a metal or alloy layer, compounded under a certain temperature and pressure, and finally cooled and processed.

The aluminum-steel composite panel is a new type of composite material that combines the advantages of aluminum plate and steel plate. It has the characteristics of high stamina, rust resistance, gorgeous look and very easy handling. It is extensively used in building, cars, ships, aerospace and other fields.

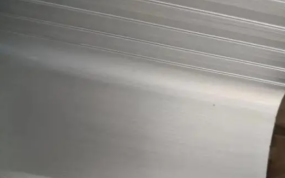

What problems will occur with aluminum steel plates after failed wire drawing and oxidation?

Although brushed oxidation is a very easy and common method, everything can be flawed. Some aluminum steel plates that fail to draw and oxidize will have the following problems.

First of all, the drawing lines may be shallow. This is most likely caused by the failure of the drawing machine to control it well. This may reduce the corrosion resistance of the aluminum plate. Then the surface of the aluminum plate is sanded. This may be because the temperature in the working tank is too high, resulting in a chemical reaction and sanding.

Then there is the uneven drawing. The common ones are that the width of the aluminum plate fed needs to be more consistent, and the positioning and drawing operation during drawing lead to inconsistent wear of the drawing roller. The operator must control the width of the aluminum plate to be consistent so that beautiful brushed aluminum plates can appear.

Precautions and characteristics of outdoor wall aluminum panels

Outdoor wall aluminum panels and plastic steel panels have gradually entered the decoration of all rooms, especially for their smooth, colorful surface, impact resistance, easy cleaning, durability, and fast construction. They have been widely used, but for some novices, the owners still It will need to be clarified. It is mainly used for aluminum and plastic panels and outdoor wall aluminum panels.

1. What are the main reasons for using aluminum composite panels for outdoor walls?

Aluminum panels are mainly used in dining rooms, bathrooms, heating hoods and bedrooms in the form of partitions. The following materials need to be paid attention to during construction. The board must be dry and flat. The aluminum and plastic panels are glued. When paying attention to the glue, it must be uniform, and the aluminum composite panel should be separated into several pieces according to the style needs when used.

2. What are the characteristics of aluminum composite panels for outdoor wall aluminum panels?

This type of product is very easy to process, making it ideal for users looking for high efficiency and time savings. Aluminum and plastic panels can significantly shorten the construction period and cost, and aluminum panels can decorate walls.

3. Check the discoloration and discoloration of outdoor wall aluminum panels and plastic panels.

This type of problem will occur mainly due to incorrect selection of boards. Generally speaking, the flavors of these products' inner and outer panels differ from the surface coatings of the two panels, which determines the different occasions it is suitable for. The surface of the boards used in the room is usually coated with resin coating, which cannot adapt to the harsh outdoor environment. If used outside the process, it will naturally accelerate the aging process and cause discoloration and discoloration.

4. Outdoor wall aluminum plate

This type of problem is usually due to the wrong choice of adhesive. Silicone rubber offers unique advantages as an ideal adhesive for aluminum panels and outdoor plastic projects. However, when purchasing aluminum plates, a special quick-drying glue is required. This glue can be used indoors as well as outdoors in environments where climate change is permanent. I believe aluminum panels are mainly used in craft manufacturing. The aluminum plate is mainly composed of five parts. The adhesive layer bonds the plate's upper and lower layers through gelation. It uses inorganic substances for internal filling. , will not be lost to the environment, and can also be applied to the external insulation of equipment pipelines. In addition, many lightweight fillers are used to make the board's performance more outstanding. However, to increase the aesthetic effect of aluminum silicate plates, coatings are often chosen to decorate the surface, increasing the aesthetics and making the plates suitable for various environments.

Supplier

TRUNNANO is a supplier of steel powder and metal clad plates with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality steel powder and metal clad plates please feel free to contact us and send an inquiry.

Inquiry us

PREVIOUS NEWS

building materials industry indispensable good material

NEXT NEWS