What is the difference between natural graphite and artificial graphite?

Russia's insistence on paying for Russian gas in rubles has rattled European countries: Greece held an emergency meeting of suppliers, the Dutch government would urge consumers to use less gas, and the French energy regulator told consumers not to panic. Russian gas meets one-third of Europe's annual energy needs.

Russia said they could expand their demand for ruble payments for other commodities, including oil, grain, fertilizer, coal, and metals, which raised the risk of recession in Europe and the US.

Moscow is expected to unveil its ruble payment plan on April 1, but it said it would not immediately ask buyers to pay for gas in rubles.

Western countries have said paying in rubles would be a breach of contract, and renegotiation could take months or longer. This uncertainty has pushed commodity market prices higher.

The supply and prices of other commodities like the natural graphite could also be affected.

Given that what is prepared from natural graphite is usually artificial graphite in the narrow sense, this paper will only analyze and discuss the differences and links between natural graphite and artificial graphite in the narrow sense.

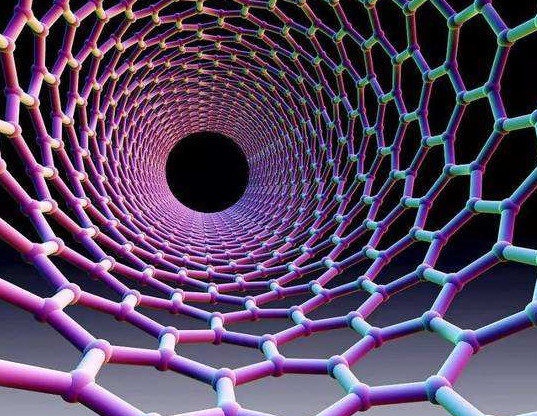

Crystal structure

The crystal development of natural graphite is relatively complete, the graphitization degree of natural flake graphite is usually above 98%, and the graphitization degree of natural microcrystalline graphite is usually below 93%.

The degree of crystal development of artificial graphite depends on the raw material and the heat treatment temperature. Generally speaking, the higher the heat treatment temperature, the higher the degree of graphitization. At present, the degree of graphitization of artificial graphite produced in the industry is usually less than 90%.

Organizational structure

Natural flake graphite is a single crystal with a relatively simple structure, with only crystallographic defects (point defects, dislocations, stacking faults, etc.), and macroscopically showing anisotropic structural characteristics. The grains of natural microcrystalline graphite are small, the grains are disorderly arranged, and there are pores after the impurities are removed, showing the isotropic structural characteristics on the macroscopic level.

Artificial graphite can be seen as a multi-phase material consisting of a graphite phase transformed by carbonaceous particles such as petroleum coke or pitch coke, a graphite phase transformed by a coal bitumen binder encapsulated around the particles, particle accumulation, or pores formed after heat treatment of coal tar binder, etc.

Physical form

Natural graphite usually exists in powder form and can be used alone, but is usually used in combination with other materials.

There are many forms of artificial graphite, including powder, fiber, and block, while artificial graphite in the narrow sense is usually blocked, which needs to be processed into a certain shape when used.

Physical and chemical properties

Natural graphite and artificial graphite have both commonalities and differences in performance. For example, both natural graphite and artificial graphite are good conductors of heat and electricity, but for graphite powders of the same purity and particle size, natural flake graphite has the best heat transfer performance and electrical conductivity, followed by natural microcrystalline graphite and artificial graphite the lowest.

Graphite has good lubricity and certain plasticity. Natural flake graphite has better crystal development, smaller friction coefficient, best lubricity, and highest plasticity, while dense crystalline graphite and cryptocrystalline graphite are second, and artificial graphite is worse.

High quality graphite manufacturer

Luoyang Moon & Star New Energy Technology Co., LTD, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.

If you are looking for graphite or lithium battery anode material, click on the needed products and send us an inquiry:sales@graphite-corp.com

Prior to the impact of COVID-19 on the chemicals and materials industry and the price of the natural graphite, many industry observers expected low to flat growth in 2021 in all regions outside Asia, with many countries seeing slower growth compared to recent years. Operational excellence has long been a hallmark of the natural graphite chemical industry, and many companies are financially able to withstand short-term dips in end-market demand due to rapid leverage from reduced capex on hand.

The analysis shows that, whatever the final course of the pandemic, we can expect the inevitable long-term effects. Workplaces are expected to slowly return to pre-COVID-19 practices. Companies investing in enterprise-wide digital initiatives saw these "payoffs" in the early pandemic environment. For more information about natural graphite, please feel free to contact us.

Inquiry us